Der Markt für white label bamboo diapers—even when built on FSC-certified wood pulp cores—continues to surge as brands chase greener credentials, premium positioning, and robust performance. This guide unpacks: the business benefits of bamboo-branded OEM lines; critical materials and certifications such as FSC-certified pulp, OEKO-TEX bamboo fiberund SGS biodegradation test standards; the production process and SAP absorbency technology; quality-assurance protocols; and a step-by-step framework for choosing the ideal Hersteller von Bambuswindeln partner.

Inhaltsübersicht

Benefits of Bamboo Diaper OEM

Partnering with a Hersteller von Bambuswindeln for your white label bamboo diapers brings clear B2B advantages:

Eco-Friendly Bamboo Diaper Private Label: Position your line as an eco-friendly bamboo diaper private label, even when using responsibly sourced wood pulp, to tap into premium green-market segments.

Biodegradable Bamboo Newborn Diapers Appeal: Parents seeking biodegradable bamboo newborn diapers are drawn by the promise of compostable packaging and gentle wood-pulp fibers certified for safety.

Superior SAP Absorbency: By blending wood pulp with high-quality superabsorbent polymer (SAP), many lines achieve fluid retention of up to 3× their weight, delivering leakproof performance on par with leading bamboo nappies.

Bamboo Diapers Wholesale Economies: Bulk production of Bambus Windeln Großhandel unlocks scale efficiencies, driving down per-unit costs while enabling competitive pricing for bamboo disposable nappies.

Organic Bamboo Nappies Positioning: Marketing your line as organic bamboo nappies—backed by FSC-certified pulp and OEKO-TEX standards—captures families willing to pay a premium for “organic” care products.

Together, these factors help you launch a kompostierbare Windeln aus Bambus oder bamboo organic diapers brand that commands attention and margin.

Material & Certification Overview

When your core is FSC-certified wood pulp, these certifications build trust in your beste Bambuswindeln offerings:

| Merkmal | FSC-Certified Wood Pulp |

|---|---|

| Renewability | Fast-growing, responsibly managed forests |

| Fiber Quality | Long fibers for durable absorbency |

| Biodegradation Rate | ~61% in 180–360 days under composting |

| Absorbency (with SAP) | Up to 3× weight |

| Zertifizierungen | FSC, OEKO-TEX® Standard 100, SGS biodegradation |

Key Certifications

FSC (Forest Stewardship Council): Guarantees pulp sourcing from responsibly managed forests—critical for any bamboo nappies brand.

OEKO-TEX® Standard 100: Tests every component (topsheet, core, backsheet) for harmful substances, supporting “skin safe” claims on bamboo diaper private label lines.

SGS Biodegradation Test: Certifies real-world compostability—e.g., leading brands pass a 50% biodegradation threshold within 180–360 days under controlled conditions.

ISO/CE/FDA Compliance: Essential for global sales of custom bamboo diaper manufacturer China products, ensuring safe materials and processes.

Production Process & Technology

Raw Material Sourcing: Secure FSC-certified pulp from sustainably managed plantations—your bedrock for “bamboo diapers” branding.

Pulp Refining & Bleaching: Employ chlorine-free ECF or TCF methods to achieve purity and softness—standard practice for bamboo nappy production.

SAP Core Integration: Mix refined wood pulp with premium SAP (e.g., sodium polyacrylate) to build an absorbent gel matrix, critical for kompostierbare Windeln aus Bambus comfort.

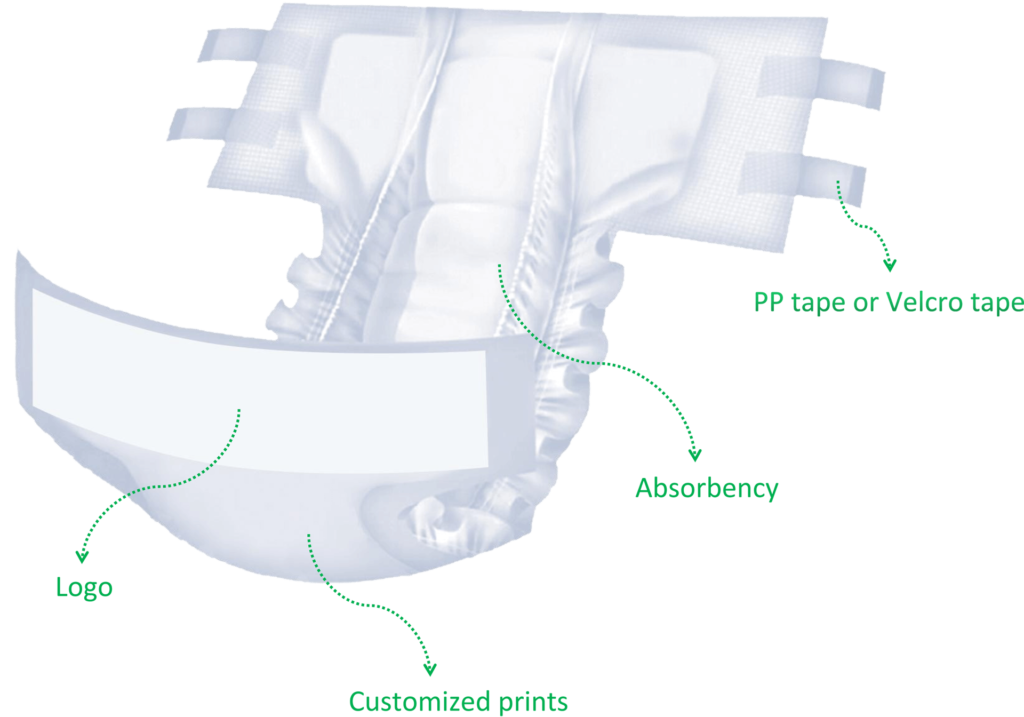

Automated Layer Assembly: Configure multi-layer construction—viscose topsheet, distribution layer, absorbent core, backsheet film, and elastics—to ensure leakproof fit in bamboo disposable nappies.

Private-Label Customization: Offer bespoke sizing, packaging, artwork, and add-on features (wetness indicators, breathable cuffs) for your Bambus Windeln Großhandel partners.

Packaging & Logistics: Utilize eco-friendly kraft or compostable films, and leverage Xiamen New EcoCare’s 45-day lead times to hit market windows reliably.

Quality Assurance—SGS, OEKO-TEX, FSC

Robust QA is non-negotiable for white label bamboo diapers branded lines:

SGS Biodegradability Testing: Confirms that biodegradable bamboo newborn diapers meet compostability targets (50%+ in 180–360 days).

OEKO-TEX® Standard 100: Ensures zero harmful chemicals in fibers and films—key for marketing organic bamboo nappies safely.

FSC Chain-of-Custody Audits: Verify pulp tracing from forest to final product, bolstering trust in your bamboo diapers sustainability claims.

In-House ISO-Certified Labs: Perform leak, absorbency, tensile strength, and dermatological tests on every batch—essential for maintaining “best bamboo diapers” status.

How to Choose Your Bamboo Diaper Partner

When evaluating a Hersteller von Bambuswindeln, use this checklist:

Zertifizierungen: Confirm FSC, OEKO-TEX, SGS biodegradation, ISO/CE/FDA credentials for your custom bamboo diaper manufacturer China.

Minimum Order Quantity (MOQ): Typical MOQs range from 10,000–20,000 packs—plan accordingly for Bambus Windeln Großhandel.

Lead Times & Capacity: Aim for a 45-day sample-to-delivery cycle to capitalize on seasonal demand for bamboo nappies.

Technical Expertise: Assess SAP integration, ECF/TCF bleaching processes, and automated assembly for consistent bamboo organic diapers quality.

Private-Label Services: Ensure full support for design, compliance labeling, and eco-packaging to differentiate your Windel Bambus offerings.

Logistics & Support: Verify FOB terms, shipping partners, and dedicated account management for seamless Einweg-Bambuswindeln supply.

Some quick questions for reference

MOQ? 100,000 diapers per size.

Lead time? 30–60 days post-sample approval.

Certifications? FSC, OEKO-TEX, SGS, ISO, CE/FDA.

Customization? Full private-label design & packaging.

Biodegradation? ~61% in 180–360 days under composting.

Find out more about New EcoCare’s products

FAQ

Q1: What is the typical MOQ for white label bamboo diapers?

A1: Most suppliers require 100,000 diapers per size, with tiered pricing tiers for Bambus Windeln Großhandel.

Q2: Which certifications are essential for eco-friendly diapers?

A2: Look for FSC (sustainable pulp), OEKO-TEX (material safety), SGS (biodegradability), and ISO/CE/FDA (global compliance).

Q3: How long do disposable bamboo nappies take to biodegrade?

A3: Under proper composting, they biodegrade approximately 61% in 180–360 days.

Q4: Can OEM suppliers handle custom packaging and branding?

A4: Yes—leading partners provide end-to-end bamboo diaper private label support, including eco-friendly packaging and compliance labeling.

Q5: What is the average lead time for white-label orders?

A5: After sample approval, expect 30–50 days for full production, with expedited rush options available.

Ready to launch your own white label bamboo diapers line—leveraging FSC-certified wood pulp for sustainability and performance?

Contact Xiamen New EcoCare today for a free OEM consultation and discover why 80+ brands trust our 20+ years of expertise and 45-day turnarounds.