Plant-based and bamboo fiber baby diapers are increasingly sourced through OEM and private label manufacturing. However, technical material limitations, machine compatibility, and procurement risks mean that not all bamboo diaper suppliers are suitable for long-term B2B partnerships. This guide explains the real material structure, production challenges, and sourcing criteria B2B buyers should evaluate when selecting a bamboo diaper OEM manufacturer.

Πίνακας περιεχομένων

What Are Plant-Based or Bamboo Fiber Diapers?

From a manufacturing perspective, plant-based or bamboo fiber diapers do not mean fully bio-based diapers.

In OEM diaper production, the term usually refers to:

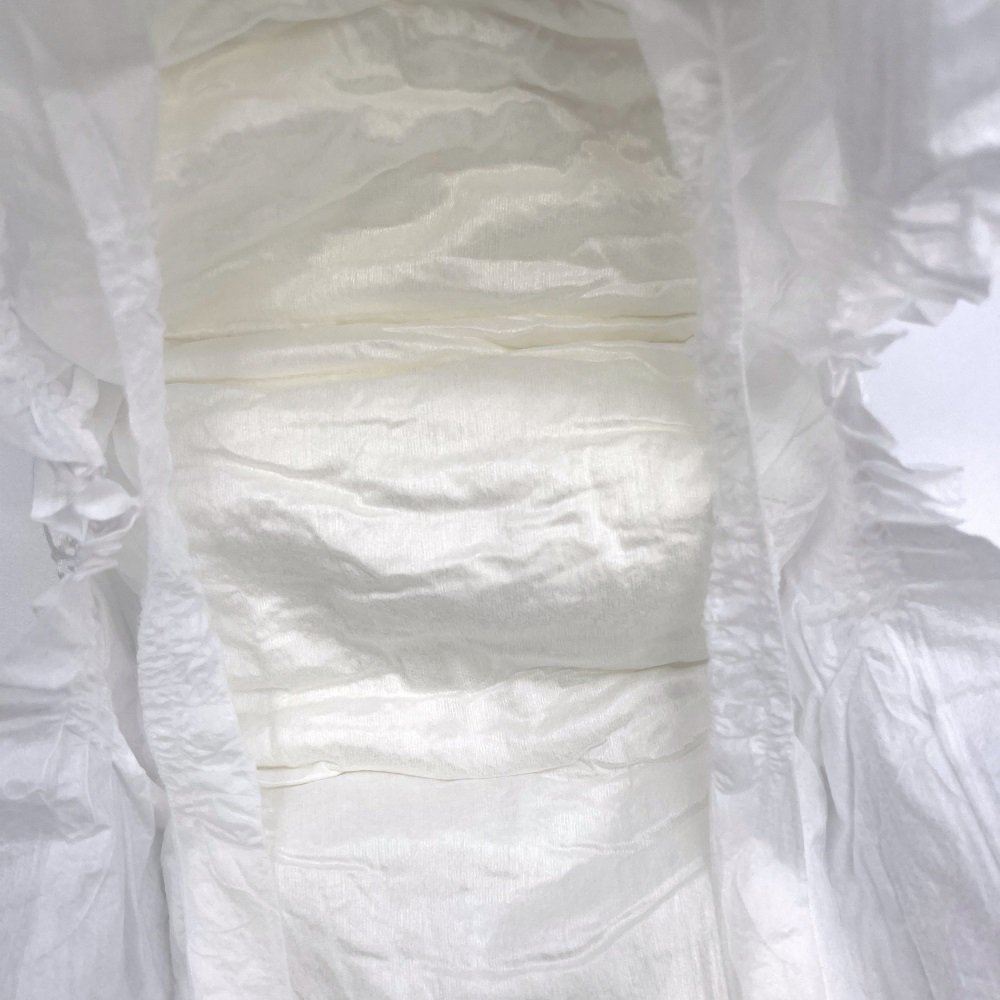

Bamboo viscose or bamboo-based nonwoven used in the topsheet (skin-contact layer)

Bamboo fiber fabric in backsheet films

Reduced petroleum-based content in selected layers

Compliance-focused material selection for infant skin safety

Why Bamboo Fiber Is the Most Common Plant-Based Diaper Material

Among plant-based options, bamboo fiber is currently the most scalable choice for OEM diaper manufacturing because:

It integrates more easily with existing diaper production lines

It provides a naturally soft surface suitable for baby skin

It allows private label brands to enter eco-positioned markets without full line redesign

However, bamboo fiber introduces technical variability that must be managed by experienced manufacturers.

Key Technical Challenges in Bamboo Diaper OEM Manufacturing

1. Raw Fiber Variability and Process Stability

Bamboo fiber is derived from natural raw materials, which introduces variability in:

Fiber length

Tensile strength

Surface smoothness

For high-speed diaper machines, this can cause:

Nonwoven tearing

Lamination instability

Increased defect rates

Experienced bamboo diaper OEM manufacturers mitigate this through material pre-testing and supplier qualification systems.

2. Absorbency Performance vs. Bamboo Marketing Claims

A bamboo topsheet does not replace the absorbent core.

Common OEM mistakes include:

Increasing bamboo content without optimizing liquid transfer

Slower absorption speed into SAP and fluff pulp

Poor rewet control affecting user experience

B2B buyers should evaluate performance data, not just bamboo percentage.

3. Breathability, Leakage, and Backsheet Engineering

Replacing traditional PE backsheet films with plant-based alternatives affects:

Breathability balance

Heat-sealing reliability

Diaper shape retention

Improper material substitution may result in leakage or deformation.

This is why pilot production testing is critical for bamboo diaper projects.

4. Production Line Compatibility and Yield Impact

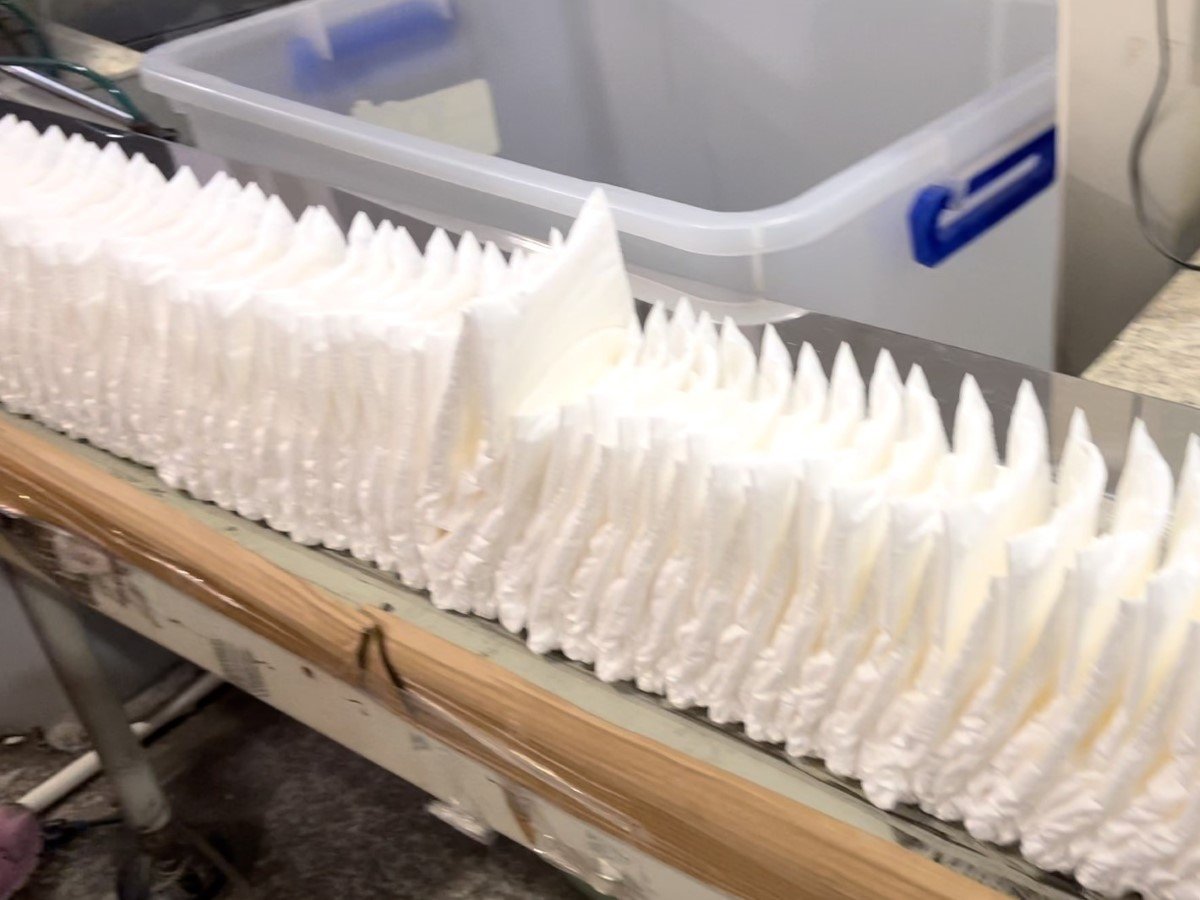

Bamboo fiber nonwoven often requires:

Adjusted machine tension

Modified cutting pressure

Slower initial production speeds

OEM factories without bamboo experience may face:

Higher waste rates

Unstable output

Inconsistent batch quality

Certifications: What B2B Buyers Should Actually Verify

Rather than focusing on logos alone, procurement teams should confirm:

Which diaper layers are certified

Whether certifications apply to raw materials or finished products

The scope of chemical safety testing

A reliable OEM partner should clearly explain:

Testing frequency

Compliance boundaries

Transparency is more valuable than excessive certification claims.

B2B Procurement Guide: How to Choose a Bamboo Diaper OEM Partner

Ask These Questions

How many bamboo fiber suppliers are approved?

What incoming material tests are performed?

How is batch consistency controlled?

Can pilot production be supported before mass orders?

What customization is available beyond packaging?

These questions signal manufacturing maturity, not sales language.

Private Label Customization That Actually Matters

Real private label diaper manufacturing includes:

Adjustable bamboo fiber ratios

Topsheet texture customization

Absorbent core structure tuning

Market-specific performance balancing

This goes far beyond logo printing.

MOQ Flexibility and Pilot Runs

Bamboo diaper programs benefit from:

Trial MOQs

Engineering feedback after test runs

Gradual scale-up

OEM partners who support this reduce launch risk for brand owners.

Cost Structure: Understanding the Real Price of Bamboo Diapers

Bamboo fiber diapers generally cost more due to:

Higher raw material costs

Lower initial production yields

Additional testing requirements

Professional OEM manufacturers explain:

Where cost differences come from

How costs can be optimized over time

Which elements are fixed vs. adjustable

Market Outlook: Why Bamboo Diaper OEM Projects Are Long-Term Plays

From a B2B strategy standpoint, bamboo diaper sourcing supports:

Long-term brand differentiation

Compliance readiness

Sustainable portfolio expansion

However, success depends on choosing experienced manufacturers, not experimental suppliers.

Why Manufacturing Experience Is Critical

At New EcoCare, bamboo fiber diaper development has focused on:

Material stability

Skin-contact safety

Scalable OEM production

Our approach prioritizes repeatability and transparency, ensuring bamboo diaper projects are commercially sustainable—not just concept-ready.

Συχνές ερωτήσεις

Q: Are bamboo fiber diapers fully biodegradable?

A: No. Most bamboo diapers use bamboo fiber in selected layers. Absorbent cores and films still contain conventional materials.

Q: Is bamboo fiber better than cotton for diapers?

A: Bamboo fiber offers better softness and moisture handling in diaper topsheets, but performance depends on overall structure.

Q: Can bamboo diapers be produced at large scale?

A: Yes, but only with OEM manufacturers experienced in bamboo material handling and yield control.

Final Takeaway for B2B Buyers

Bamboo diaper OEM manufacturing offers real opportunities—but only when technical limits, cost structure, and production risks are clearly understood.

For B2B buyers sourcing:

Bamboo fiber baby diapers

Private label diaper manufacturing

Long-term OEM partnerships

Technical clarity matters more than claims.

Written by New EcoCare

OEM & private label manufacturer specializing in bamboo fiber baby diapers and customized hygiene solutions.