Πίνακας περιεχομένων

I. Εισαγωγή

Οι πάνες μίας χρήσης για μωρά αποτελούν βασικό μέρος της βρεφικής φροντίδας, σχεδιασμένες για να παρέχουν άνεση, υγιεινή και προστασία στα μωρά. Καθώς οι γονείς συνεχίζουν να αναζητούν πάνες που προσφέρουν ανώτερη απορρόφηση, απαλότητα και προστασία του δέρματος, η αγορά πάνες έχει γνωρίσει σημαντικές καινοτομίες με την πάροδο των ετών. Η ζήτηση για φιλικά προς το περιβάλλον και βιώσιμα προϊόντα ωθεί επίσης τους κατασκευαστές να προσαρμοστούν και να εξελιχθούν. Σε αυτόν τον ολοκληρωμένο οδηγό, θα εμβαθύνουμε στη δομή των βρεφικών πάνες, τα υλικά που χρησιμοποιούνται, τις τάσεις της αγοράς και τις σημαντικές εκτιμήσεις για την υγεία, με πληροφορίες για το ρόλο των Xiamen νέα EcoCare, ένας κορυφαίος κατασκευαστής γνωστός για την υψηλή ποιότητα των προϊόντων του, βιοδιασπώμενες λύσεις πάνας.

II. Δομή των βρεφικών πάνες

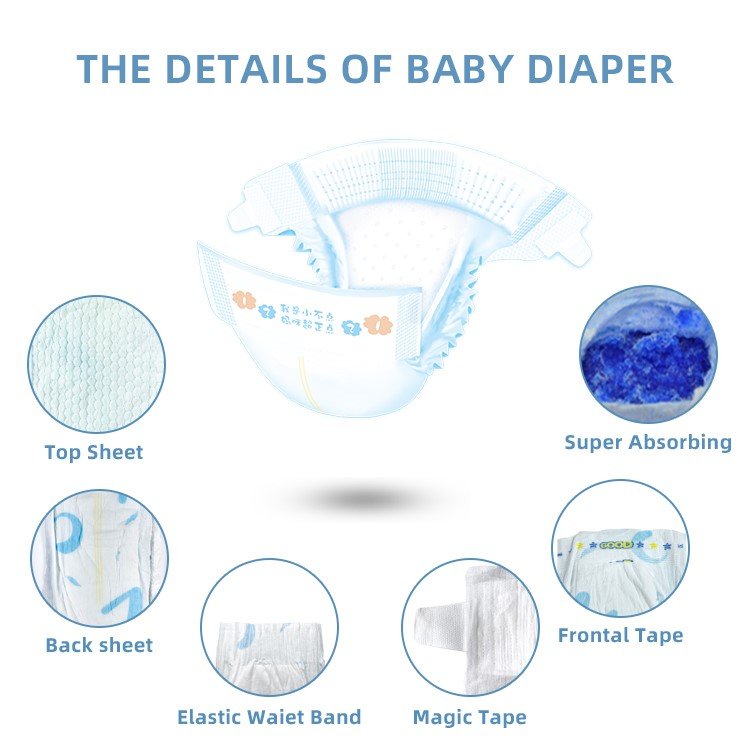

Ο σχεδιασμός των σύγχρονων πάνες μίας χρήσης έχει εξελιχθεί ώστε να εξασφαλίζει τη βέλτιστη άνεση και προστασία για τα μωρά. Μια τυπική πάνα αποτελείται από διάφορα στρώματα, καθένα από τα οποία εξυπηρετεί συγκεκριμένο σκοπό για τη διατήρηση της στεγνότητας και την αποφυγή διαρροών. Τα στρώματα αυτά είναι: Η πάνα είναι μια από τις μεγαλύτερες στρώσεις που χρησιμοποιούνται για την προστασία του σώματος:

Επιφανειακό στρώμα (βαμβάκι και ίνες)

Αυτό το στρώμα έρχεται σε άμεση επαφή με το δέρμα του μωρού και παίζει καθοριστικό ρόλο στην απορρόφηση των υγρών. Έχει σχεδιαστεί για να είναι μαλακό, μη ερεθιστικό και υποαλλεργικό, μειώνοντας τον κίνδυνο εξανθήματος από την πάνα. Τυπικά κατασκευασμένο από βαμβάκι ή μη υφασμένες ίνες, αυτό το στρώμα βοηθά στη μετακίνηση της υγρασίας από την επιφάνεια στο επόμενο στρώμα.

Στρώμα εκτροπής (Στρώμα που κλειδώνει το νερό)

Τοποθετημένο κάτω από το επιφανειακό στρώμα, αυτό το στρώμα έχει σχεδιαστεί για να διοχετεύει γρήγορα την υγρασία στον απορροφητικό πυρήνα. Συνήθως είναι κατασκευασμένο από μη υφασμένο ύφασμα που απορροφά γρήγορα, το οποίο εξασφαλίζει ότι η υγρασία κλειδώνεται γρήγορα για να κρατήσει το μωρό στεγνό.

Απορροφητικός πυρήνας

Ο απορροφητικός πυρήνας είναι το πιο σημαντικό στρώμα μιας πάνας. Συνήθως περιέχει Σούπερ απορροφητικό πολυμερές (SAP) και ξυλοπολτός, τα οποία συνεργάζονται για να απορροφήσουν και να κλειδώσουν την υγρασία. Το SAP είναι ένα εξαιρετικά αποτελεσματικό υλικό που μπορεί να απορροφήσει πολλές φορές το βάρος του σε υγρό, διατηρώντας το μωρό στεγνό για μεγάλα χρονικά διαστήματα. Η χρήση του SAP επέτρεψε στις πάνες να γίνουν λεπτότερες, διατηρώντας παράλληλα υψηλή απορροφητικότητα.

Στρώμα που κλειδώνει το νερό (αντι-αντίστροφη διαρροή)

Αυτό το στρώμα είναι υπεύθυνο για την πρόληψη των διαρροών και τη διασφάλιση ότι η υγρασία παραμένει εντός της πάνας, ακόμη και όταν το μωρό κινείται ή κοιμάται. Το στρώμα που κλειδώνει το νερό είναι συνήθως κατασκευασμένο από συνδυασμό μεμβράνης πολυαιθυλενίου (PE) και μη υφασμένου υφάσματος, παρέχοντας ένα φράγμα που δεν επιτρέπει διαρροές.

Κάτω στρώμα (ταινία PE ή ταινία PE + μη υφασμένο ύφασμα)

Το κάτω στρώμα μιας πάνας έχει σχεδιαστεί για να διασφαλίζει ότι η υγρασία περιορίζεται και δεν διαφεύγει. Παρέχει επίσης δυνατότητα αναπνοής στην πάνα, η οποία συμβάλλει στη μείωση του κινδύνου ερεθισμού του δέρματος. Αυτό το στρώμα είναι συχνά κατασκευασμένο από Μεμβράνη PE, ένα υλικό που είναι εύκαμπτο, στεγανό και άνετο.

Προστασία κατά της διαρροής

Πολλές σύγχρονες πάνες διαθέτουν πρόσθετα εμπόδια κατά της διαρροής, όπως ελαστικές μανσέτες ποδιών και πλευρικά εμπόδια, για την αποφυγή διαρροών, ειδικά κατά τη διάρκεια ενεργού παιχνιδιού ή ολονύκτιας χρήσης.

Αυτοκόλλητα αυτοκόλλητα

Τα αυτοκόλλητα αυτοκόλλητα στις πάνες χρησιμοποιούνται για να στερεώσουν την πάνα στη θέση της. Συχνά είναι κατασκευασμένα από μη υφασμένο ύφασμα ή Velcro και επιτρέπουν την εύκολη προσαρμογή για να εξασφαλίσουν μια άνετη και άνετη εφαρμογή.

III. Υλικά που χρησιμοποιούνται στις βρεφικές πάνες

Τα υλικά που χρησιμοποιούνται στις βρεφικές πάνες έχουν εξελιχθεί σημαντικά για να εξασφαλίσουν καλύτερες επιδόσεις, άνεση και περιβαλλοντική βιωσιμότητα. Τα βασικά υλικά περιλαμβάνουν:

Μη υφασμένο ύφασμα

Τα μη υφασμένα υφάσματα χρησιμοποιούνται για την επιφάνεια και τα στρώματα εκτροπής των πάνες. Έχουν σχεδιαστεί για να είναι μαλακά, αναπνέοντα και απαλά στο δέρμα του μωρού, ενώ παράλληλα είναι ιδιαίτερα απορροφητικά.

Σούπερ απορροφητικό πολυμερές (SAP)

SAP είναι το κύριο συστατικό του απορροφητικού πυρήνα, επιτρέποντας στις πάνες να απορροφούν μεγάλες ποσότητες υγρών χωρίς να γίνονται ογκώδεις. Το υλικό αυτό είναι ικανό να απορροφά έως και 30 φορές το βάρος του σε υγρό, καθιστώντας το κρίσιμο συστατικό στις σύγχρονες πάνες.

Πολυαιθυλένιο (PE) και πολυπροπυλένιο (PP)

Αυτά τα υλικά χρησιμοποιούνται συνήθως για τα εξωτερικά στρώματα και τα φράγματα στεγανότητας. Το PE παρέχει την απαραίτητη στεγανοποίηση, ενώ το PP χρησιμοποιείται για το μη υφασμένο ύφασμα και άλλα στοιχεία που απαιτούν αντοχή και ευελιξία.

Ξυλοπολτός

Στον απορροφητικό πυρήνα χρησιμοποιείται ξυλοπολτός για να βοηθήσει στη διανομή της υγρασίας και να ενισχύσει τη συνολική απορροφητικότητα της πάνας. Συχνά συνδυάζεται με SAP για ένα πιο αποτελεσματικό σύστημα συγκράτησης της υγρασίας.

Καινοτομίες υλικών:

Τα τελευταία χρόνια, υπάρχει μια ώθηση προς τη χρήση φιλικών προς το περιβάλλον και βιοδιασπώμενων υλικών. Για παράδειγμα, η χρήση ίνες μπαμπού και άλλων βιώσιμων υλικών γίνεται όλο και πιο δημοφιλής στη βιομηχανία πάνες. Τα υλικά αυτά δεν είναι μόνο απαλά για το δέρμα του μωρού, αλλά συμβάλλουν επίσης στη μείωση των περιβαλλοντικών επιπτώσεων των πάνες μιας χρήσης.

IV. Τάσεις και σύνθεση της αγοράς

Η αγορά βρεφικών πάνες αναπτύσσεται ραγδαία λόγω παραγόντων όπως η αυξημένη αστικοποίηση, η αύξηση των διαθέσιμων εισοδημάτων και η αυξανόμενη ευαισθητοποίηση σε θέματα υγιεινής και φροντίδας του δέρματος. Σύμφωνα με πρόσφατες εκθέσεις της αγοράς:

Κατανομή μεριδίων αγοράς:

Η παγκόσμια αγορά κυριαρχείται από μεγάλες μάρκες όπως Pampers (50%), Mamypoko (36%) και άλλες τοπικές μάρκες (14%). Οι εταιρείες αυτές συνεχίζουν να καινοτομούν στο σχεδιασμό των προϊόντων, τη χρήση υλικών και τη βιωσιμότητα για να κατακτήσουν μεγαλύτερο μερίδιο της αυξανόμενης αγοράς.

Παγκόσμια ζήτηση για πάνες φιλικές προς το περιβάλλον:

Καθώς οι προτιμήσεις των καταναλωτών μετατοπίζονται προς πιο βιώσιμα και φιλικά προς το περιβάλλον προϊόντα, κατασκευαστές όπως οι Xiamen νέα EcoCare επικεντρώνονται στην παραγωγή βιοδιασπώμενες πάνες με βάση το μπαμπού. Η στροφή αυτή οφείλεται στην αυξανόμενη συνειδητοποίηση των περιβαλλοντικών επιπτώσεων των πάνες από πλαστικό και στην ανάγκη για καλύτερη διαχείριση των αποβλήτων.

V. Σκέψεις για την υγεία και την ασφάλεια

Ενώ οι πάνες μίας χρήσης είναι απαραίτητες για τη διατήρηση της υγιεινής, υπάρχουν ανησυχίες για την υγεία όσον αφορά ορισμένα από τα υλικά που χρησιμοποιούνται, ιδίως φθαλικές ενώσεις, οι οποίες είναι χημικές ουσίες που βρίσκονται συνήθως στα πλαστικά.

Φθαλικές ενώσεις στις πάνες:

Οι φθαλικές ενώσεις χρησιμοποιούνται για να κάνουν τα πλαστικά πιο εύκαμπτα, αλλά έχουν συνδεθεί με διάφορους κινδύνους για την υγεία, συμπεριλαμβανομένης της ενδοκρινικής διαταραχής. Μελέτες έχουν δείξει ότι τα μωρά είναι ιδιαίτερα ευάλωτα στην έκθεση σε φθαλικούς εστέρες, η οποία μπορεί να επηρεάσει την ανάπτυξή τους. Μια μελέτη του 2019 από το Πανεπιστήμιο του Ιλινόις εντόπισε φθαλικές ενώσεις όπως DBP και DEHP σε πάνες σε συγκεντρώσεις έως και 1609,7 ppb.

Κίνδυνοι για την υγεία:

Οι πρωταρχικές ανησυχίες για την υγεία που σχετίζονται με τους φθαλικούς εστέρες είναι η πιθανότητα να διαταράξουν το ενδοκρινικό σύστημα, γεγονός που μπορεί να έχει μακροπρόθεσμες επιπτώσεις στην ορμονική ανάπτυξη των βρεφών. Επιπλέον, η έκθεση σε ορισμένες χημικές ουσίες μπορεί να αυξήσει τον κίνδυνο ερεθισμού του δέρματος και εξανθήματος από την πάνα.

Ασφαλέστερες εναλλακτικές λύσεις:

Σε απάντηση σε αυτές τις ανησυχίες, πολλοί κατασκευαστές πάνες, συμπεριλαμβανομένων των Xiamen νέα EcoCare, έχουν δεσμευτεί να χρησιμοποιούν Χωρίς φθαλικό εστέρα υλικά και υποαλλεργικά συστατικά για να διασφαλίζεται η ασφάλεια και η ευημερία των μωρών.

VI. Πρόσφατες εξελίξεις στο σχεδιασμό βρεφικών πάνες

Καθώς η τεχνολογία των πάνες εξελίσσεται, οι κατασκευαστές αναζητούν συνεχώς τρόπους βελτίωσης της απόδοσης, της άνεσης και της βιωσιμότητας των πάνες. Οι βασικές τάσεις περιλαμβάνουν:

Λεπτότερες, πιο απορροφητικές πάνες:

Οι πάνες γίνονται όλο και πιο λεπτές χωρίς να θυσιάζουν την απορροφητικότητα. Αυτό οφείλεται στην αυξημένη χρήση της SAP, η οποία επιτρέπει υψηλή απορροφητικότητα σε ένα λεπτό, άνετο σχεδιασμό. Οι λεπτότερες πάνες διευκολύνουν τα μωρά να μετακινούνται, παρέχοντας μεγαλύτερη άνεση.

Πάνες φιλικές προς το περιβάλλον:

Με τις περιβαλλοντικές ανησυχίες να αποτελούν προτεραιότητα για πολλούς γονείς, οι επιλογές για πάνες φιλικές προς το περιβάλλον αυξάνονται συνεχώς. Οι πάνες με βάση το μπαμπού και οι βιοδιασπώμενες πάνες κερδίζουν δημοτικότητα, καθώς όλο και περισσότεροι γονείς αναζητούν βιώσιμες εναλλακτικές λύσεις στις παραδοσιακές πάνες με βάση το πλαστικό.

Χαρακτηριστικά προστασίας του δέρματος:

Οι πάνες σχεδιάζονται πλέον με γνώμονα την καλύτερη προστασία του δέρματος. Τα μαλακά υλικά, οι υποαλλεργικές ιδιότητες και η χρήση αλόης ή βιταμίνης Ε στο επιφανειακό στρώμα βοηθούν στην πρόληψη του εξανθήματος και του ερεθισμού της πάνας.

VII. OEM πάνες μωρών

Xiamen νέα EcoCare προσφέρει μια σειρά παιδικών πάνες OEM προσαρμοσμένες στις διαφορετικές ανάγκες των πελατών. Παρέχουμε δύο βασικούς τύπους βρεφικών πάνες που μπορούν να προσαρμοστούν πλήρως όσον αφορά το υλικό και τα γραφικά. Κάθε τύπος έχει μοναδικά χαρακτηριστικά, καθιστώντας τον κατάλληλο για διαφορετικές αγορές ή ομάδες πελατών.

Ποια μέρη της πάνας μπορούν να προσαρμοστούν

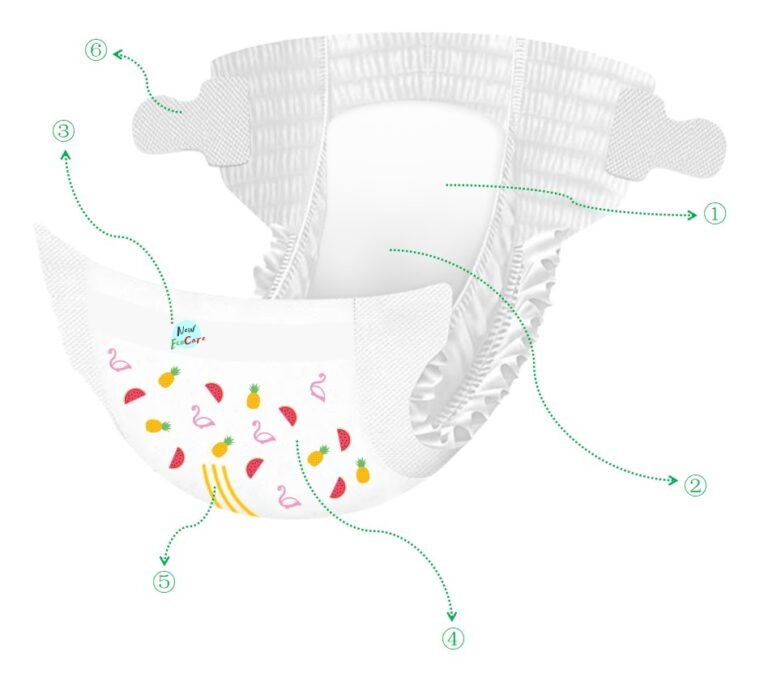

1. Παιδική πάνα τύπου ταινίας

① Επάνω φύλλο

Μαλακό, αναπνεύσιμο μη υφασμένο ύφασμα σε ανάγλυφο, διάτρητο ή μονόχρωμο στυλ.

② Απορροφητικός πυρήνας

Πολύ λεπτός σύνθετος πυρήνας ή SAP αναμεμειγμένο με ξυλοπολτό.

③ Μετωπική ταινία

Μη υφασμένη ταινία, ταινία με βούρτσα (σουέτ) ή πλεκτή ταινία (πλέγμα ή δίχτυ)

④ Οπισθόφυλλο με τις αγαπημένες σας εκτυπώσεις

Μπορείτε να εκτυπώσετε το λογότυπό σας και το αγαπημένο σας μοτίβο στο πίσω φύλλο των πάνες.

⑤ Ένδειξη υγρασίας

Μπορεί να είναι 1, 2 ή 3 γραμμές σύμφωνα με το αίτημα.

⑥ Μαγική ταινία

Μαλακή, φαρδιά ταινία (20% φαρδύτερη) διατίθεται προαιρετικά για επιπλέον άνεση.

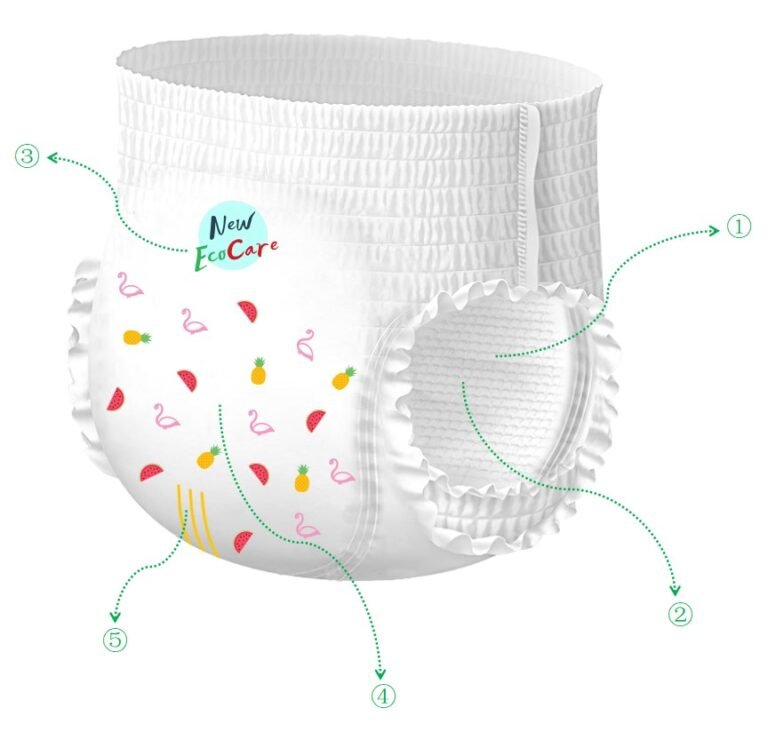

2. Βρεφική πάνα σε στυλ Pull-up

① Επάνω φύλλο

Μαλακό, αναπνεύσιμο μη υφασμένο ύφασμα σε ανάγλυφο, διάτρητο ή μονόχρωμο στυλ.

② Απορροφητικός πυρήνας

Πολύ λεπτός σύνθετος πυρήνας ή SAP αναμεμειγμένο με ξυλοπολτό.

③ Μετωπική ταινία

Μπορεί να εκτυπώσει το λογότυπό σας ή οποιαδήποτε μοτίβα σύμφωνα με το αίτημα

④ Οπισθόφυλλο με τις αγαπημένες σας εκτυπώσεις

Μπορείτε να εκτυπώσετε το λογότυπό σας και το αγαπημένο σας μοτίβο στο πίσω φύλλο των πάνες.

⑤ Ένδειξη υγρασίας

Μπορεί να είναι 1, 2 ή 3 γραμμές σύμφωνα με το αίτημα.

VIII. Διαδικασία προσαρμογής πάνες μωρών

Αν είστε νέοι στο Προσαρμογή πάνες μωρών, ακολουθεί ένα απλό χρονοδιάγραμμα που θα σας βοηθήσει να κατανοήσετε τα βήματα και το χρόνο που χρειάζεται κάθε μέρος της διαδικασίας:

Διαδικασία για παραγγελίες OEM

Ανάλυση και αξιολόγηση της ζήτησης

Κατανόηση των απαιτήσεων, των στόχων και των προδιαγραφών των προϊόντων του πελάτη για την παροχή προσαρμοσμένων λύσεων.

Καταιγισμός ιδεών και αρχική ιδέα

Συνεργασία με τον πελάτη για την ανάπτυξη ιδεών και την πρόταση ιδεών προϊόντος.

Επιβεβαίωση ποιότητας (παρέχονται δείγματα)

Προετοιμάζετε και παρέχετε δείγματα προϊόντων για δοκιμές ποιότητας και έγκριση.

Επιβεβαίωση παραγγελίας και υπογραφή σύμβασης

Οριστικοποιήστε τις λεπτομέρειες του προϊόντος, επιβεβαιώστε την παραγγελία και υπογράψτε μια επίσημη συμφωνία.

Πληρωμή του τέλους OEM και της προκαταβολής

Λάβετε την προκαταβολή για να ξεκινήσει η διαδικασία παραγωγής.

Σχεδιασμός και ανάπτυξη

Δημιουργία λεπτομερών σχεδίων και διασφάλιση ότι όλες οι πτυχές του προϊόντος πληρούν τις συμφωνημένες προδιαγραφές.

Μαζική παραγωγή

Ξεκινήστε τη μαζική παραγωγή τηρώντας πρότυπα υψηλής ποιότητας.

Διασφάλιση και έλεγχος ποιότητας

Αυστηροί ποιοτικοί έλεγχοι σε κάθε στάδιο παραγωγής.

Πληρωμή ισοζυγίου

Πληρωμή υπολοίπου πριν από την αποστολή.

Παράδοση

Φροντίστε για την έγκαιρη παράδοση στον πελάτη.

IX. Το μέλλον των βρεφικών πάνες

Η αγορά βρεφικών πάνες είναι έτοιμη για συνεχή ανάπτυξη, με τις μελλοντικές εξελίξεις να επικεντρώνονται σε:

Βιωσιμότητα:

Καθώς όλο και περισσότεροι καταναλωτές ζητούν φιλικές προς το περιβάλλον επιλογές, οι βιοδιασπώμενες πάνες από ίνες μπαμπού και άλλα βιώσιμα υλικά θα γίνονται όλο και πιο συνηθισμένες.

Υγεία και άνεση:

Οι κατασκευαστές θα συνεχίσουν να δίνουν προτεραιότητα στην υγεία και την άνεση του δέρματος, με βελτιωμένους σχεδιασμούς και τη χρήση πιο ήπιων υλικών για την πρόληψη των εξανθημάτων της πάνας.

Έξυπνες πάνες:

Καινοτομίες όπως έξυπνες πάνες, τα οποία ενσωματώνουν δείκτες υγρασίας και αισθητήρες υγρασίας, αναμένεται να γίνουν πιο διαδεδομένα, προσφέροντας ευκολία στους γονείς και μεγαλύτερη άνεση στα μωρά.

Συμπέρασμα

Παιδικές πάνες έχουν διανύσει πολύ δρόμο, με βελτιώσεις στην άνεση, τις επιδόσεις και τον περιβαλλοντικό αντίκτυπο. Καθώς η ζήτηση για βιώσιμα προϊόντα συνεχίζει να αυξάνεται, κατασκευαστές όπως οι Xiamen νέα EcoCare είναι πρωτοπόροι στην παραγωγή υψηλής ποιότητας, βιοδιασπώμενων πάνες. Το μέλλον των βρεφικών πάνες φαίνεται πολλά υποσχόμενο, με συνεχείς καινοτομίες στα υλικά, το σχεδιασμό και τη βιωσιμότητα. Είτε οι γονείς αναζητούν μια πιο απορροφητική, λεπτότερη πάνα είτε μια πάνα κατασκευασμένη από φιλικά προς το περιβάλλον υλικά, η βιομηχανία πάνες θα συνεχίσει να εξελίσσεται για να καλύψει αυτές τις ανάγκες.