Il pannolino per bambini Il mercato dei prodotti per l'infanzia è uno dei settori più dinamici e redditizi a livello globale, guidato dalla crescente domanda di igiene, convenienza e prodotti di alta qualità. Poiché i genitori danno sempre più priorità al comfort, alla sicurezza e alla salute dei loro bambini, la necessità di soluzioni affidabili per i pannolini continua a crescere. Se siete interessati a entrare nel settore come produttori, grossisti o dettaglianti, questa guida completa vi illustrerà tutto ciò che dovete sapere per avere successo nel settore dei pannolini per bambini.

Indice dei contenuti

1. Introduzione al mercato dei pannolini per bambini

1.1 Panoramica del mercato globale

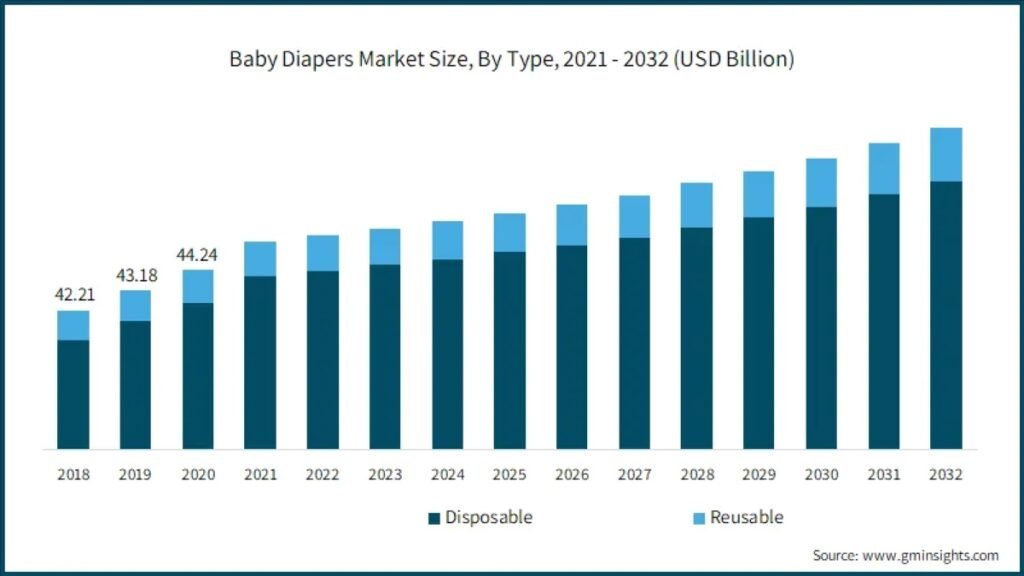

Il mercato globale dei pannolini per bambini ha registrato una crescita robusta e si prevede che il settore raggiungerà $80,5 miliardi entro il 2030con un tasso di crescita annuo composto (CAGR) di circa 5.3% dal 2024 al 2030. Questa crescita è guidata da diversi fattori chiave:

- Aumento dei tassi di natalità: Mentre i tassi di natalità sono rallentati in alcuni paesi sviluppati, i mercati emergenti in regioni quali Asia, Africa e Sud Americastanno registrando una crescita significativa, contribuendo all'aumento della domanda di pannolini per bambini.

- Aumento del reddito disponibile: Con l'aumento del reddito familiare, molti genitori optano per marchi di pannolini di qualità superiore che offrono maggiore comfort, assorbenza e sostenibilità.

- Maggiore consapevolezza dell'igiene: I genitori di oggi sono più attenti all'igiene e alla salute del bambino, il che ha portato a un aumento della domanda di pannolini che offrono prestazioni superiori.

1.2 Tipi di pannolini nel mercato

Il mercato dei pannolini per bambini soddisfa un'ampia gamma di esigenze dei consumatori. Alcuni dei principali tipi di pannolini sono:

- Pannolini per bambini: Il tipo più comune, che comprende pannolini a nastro e pantaloni pull-up.

- Pannolini per adulti: Progettato per l'incontinenza, in particolare per gli anziani e i pazienti affetti da patologie.

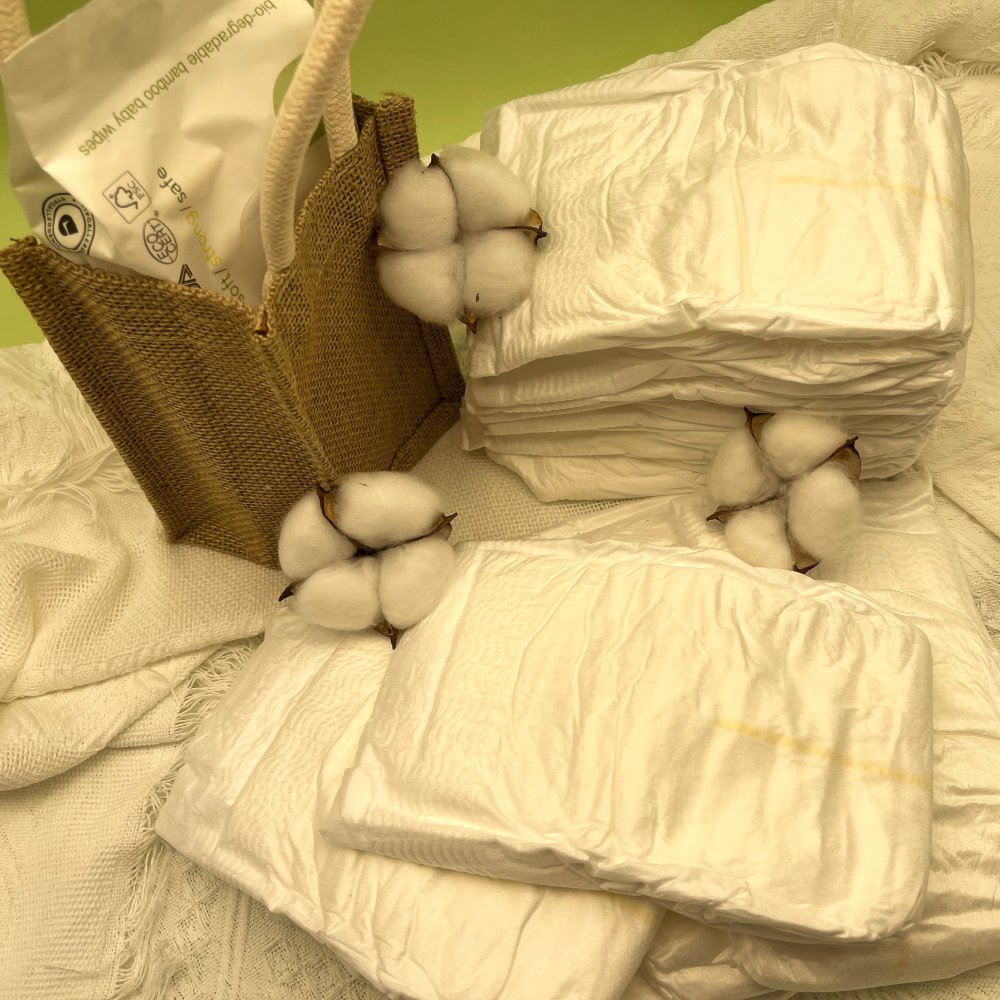

- Pannolini ecologici: Sempre più diffusi tra i consumatori attenti all'ambiente, sono realizzati con materiali biodegradabili quali fibra di bambù e cotone biologico.

- Pannolini specializzati: Per scopi specifici, come ad esempio pannolini da bagno, pannolini ipoallergenicie quelli con caratteristiche avanzate per le pelli sensibili.

La Cina è il leader mondiale nella produzione di pannolini e rappresenta una quota importante delle esportazioni mondiali grazie ai suoi impianti di produzione avanzati e alla manodopera conveniente.

2. Capire le specifiche dei pannolini per bambini

2.1 Taglie comuni dei pannolini

I pannolini sono progettati per adattarsi a bambini di età e peso diversi. Le categorie di taglie più comuni sono:

- Neonato (NB): Per bambini di peso fino a 5 kg (11 libbre).

- Piccolo (S): Per bambini di 4-8 kg (8,8-17,6 libbre).

- Medio (M): Per bambini di 6-11 kg (13,2-24,3 libbre).

- Grande (L): Per bambini di 9-14 kg (19,8-30,8 libbre).

- Extra Large (XL): Per bambini di peso superiore a 12 kg (26,4 libbre).

La scelta della taglia giusta è fondamentale per garantire il comfort ed evitare perdite. Una taglia sbagliata può provocare perdite, eruzioni cutanee o disagi che possono danneggiare la reputazione di un marchio.

2.2 Materiali utilizzati nei pannolini

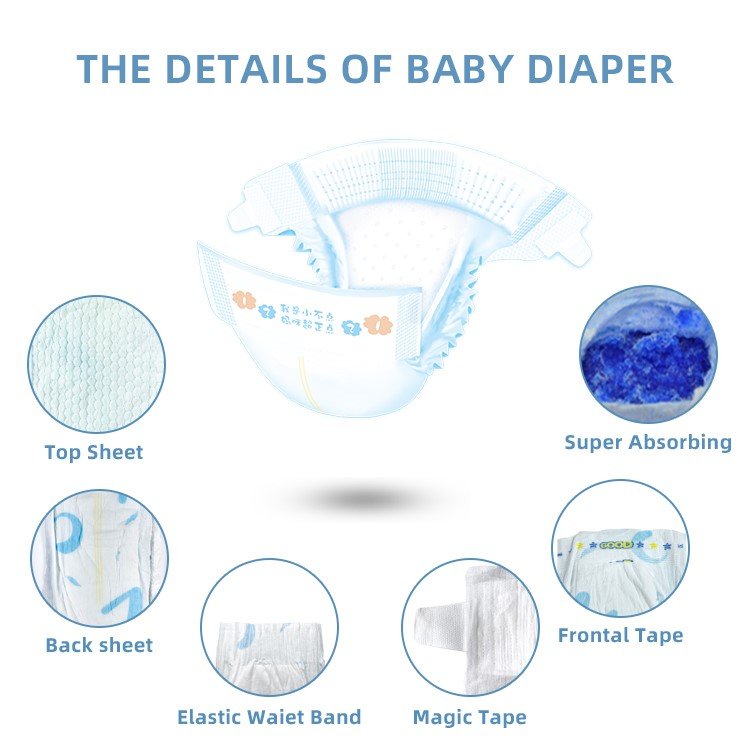

La composizione di un pannolino di alta qualità è fondamentale per le prestazioni e il comfort. Un tipico pannolino è composto da diversi strati di materiale:

- Foglio superiore (strato interno): Morbido tessuto non tessuto che mantiene la pelle del bambino asciutta, allontanando l'umidità.

- Nucleo assorbente: Si tratta di un prodotto a base di polimeri superassorbenti (SAP)e polpa di lanugineche bloccano l'umidità e prevengono le perdite.

- Foglio posteriore (strato esterno): Strato impermeabile che impedisce la fuoriuscita di liquidi sui vestiti e sulla biancheria da letto.

- Componenti elastici: Assicurano che il pannolino aderisca perfettamente alla vita e alle gambe, evitando perdite.

- Additivi opzionali: Alcuni pannolini includono aloe vera, vitamina Eo altri ingredienti per la cura della pelle per lenire e proteggere la pelle sensibile.

Con l'aumento della domanda di prodotti ecologici, molti produttori si stanno concentrando sull'uso di fibra di bambù, SAP biodegradabilee altri materiali sostenibili.

3. Processo di produzione dei pannolini per bambini

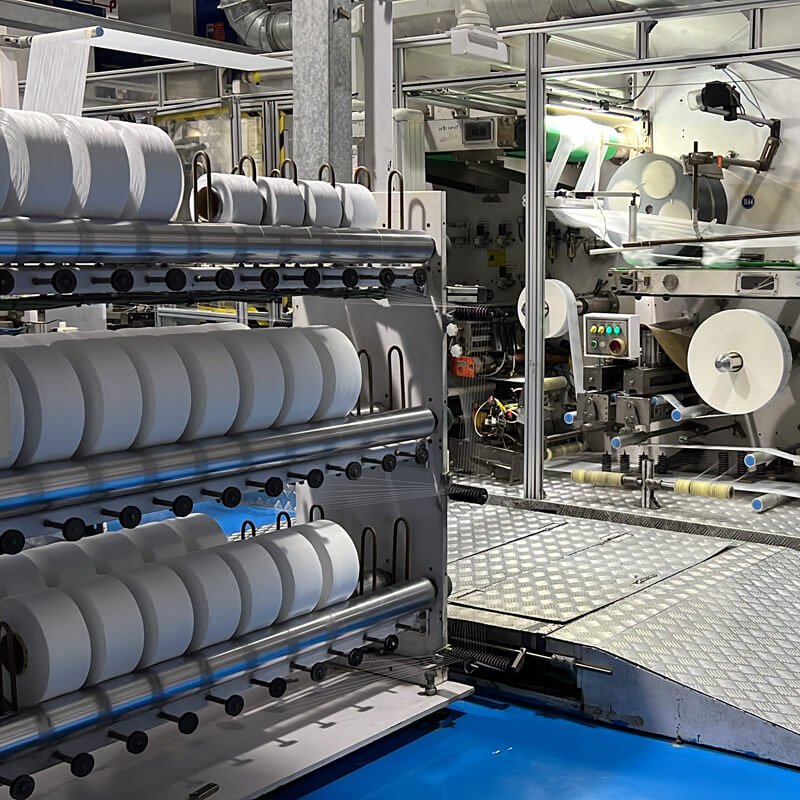

Il processo di produzione dei pannolini prevede diverse fasi, ognuna delle quali richiede precisione e tecnologie avanzate per ottenere un prodotto di alta qualità.

3.1 Preparazione della materia prima

- Produzione di tessuto non tessuto: Le fibre polimeriche vengono fuse, filate e incollate per formare un tessuto morbido e traspirante per il lenzuolo superiore del pannolino e gli altri strati.

- Formazione del nucleo assorbente: Il polimero superassorbente (SAP) e la pasta di cellulosa vengono mescolati per creare l'anima, che viene poi pressata in fogli di spessore e densità adeguati.

3.2 Processo di assemblaggio

- Stratificazione: Il nucleo assorbente è inserito tra lo strato interno in tessuto non tessuto e lo strato esterno impermeabile.

- Caratteristiche elastiche: Filati di spandex o altri materiali elastici sono aggiunti alla vita e ai polsini delle gambe per garantire una vestibilità aderente e a prova di perdite.

- Taglio e sagomatura: I pannolini vengono tagliati in forma e dotati di chiusure adesive o di elastici, a seconda del modello.

3.3 Controllo di qualità

Misure rigorose di controllo della qualità sono essenziali per garantire che ogni pannolino soddisfi gli standard più elevati. I test comprendono:

- Assorbenza: Assicura che il pannolino possa assorbire e trattenere l'umidità senza perdite.

- Prevenzione delle perdite: Test sull'efficacia dei polsini delle gambe e della fascia in vita per prevenire le perdite.

- Facilità d'uso per la pelle: Assicurarsi che i materiali utilizzati siano delicati per la pelle sensibile del bambino.

3.4 Imballaggio

I pannolini finiti vengono confezionati in imballaggi per la vendita al dettaglio o all'ingrosso. Può trattarsi di confezioni di marca o OEM, a seconda che i pannolini vengano venduti con un marchio privato o con un marchio del produttore.

4. Avviare un'attività di pannolini per bambini

4.1 Perché investire nel settore dei pannolini?

Il mercato globale dei pannolini per bambini si prevede che raggiungerà $80,5 miliardi entro il 2030con significative opportunità di crescita grazie a:

- Domanda elevata grazie ai tassi di natalità costanti, soprattutto nei mercati emergenti.

- Opportunità nei prodotti ecologici e di qualità.

- Potenziale di innovazionenel design, nei materiali e nelle tecniche di produzione dei pannolini.

4.2 Passi fondamentali per avviare un'attività di pannolini

- Ricerca di mercato: La comprensione dei dati demografici e delle preferenze dei clienti è fondamentale per posizionare il prodotto sul mercato.

- Modello di business: Decidete se volete produrre, distribuire o vendere direttamente ai consumatori. La produzione richiede un investimento maggiore, ma offre un maggiore controllo sulla qualità del prodotto e sul marchio. La vendita all'ingrosso o al dettaglio richiede meno capitale e si concentra maggiormente sulla distribuzione.

- Selezionare i fornitori o i produttori: Per la vendita all'ingrosso o etichettatura privataScegliete produttori affidabili in grado di soddisfare gli standard di qualità e di consegnare in tempo. Cercate fabbriche con certificazioni come FDA, ISO, e CE.

- Sviluppo del marchio: Stabilire un'identità di marca unica, che comprenda il packaging, le caratteristiche del prodotto e valori come la sostenibilità o il comfort.

5. Opportunità commerciali all'ingrosso

5.1 Vantaggi della vendita all'ingrosso

Le attività di vendita all'ingrosso offrono diversi vantaggi a chi vuole entrare nel mercato dei pannolini senza il capitale e la complessità della produzione:

- Riduzione dei costi operativi: Si evitano i costi associati alla creazione e alla manutenzione di uno stabilimento di produzione.

- Accesso a prodotti di alta qualità: Collaborare con produttori affermati per offrire prodotti ben fatti.

- Opzioni di personalizzazione: Molti produttori offrono OEM (Original Equipment Manufacturer) servizi, consentendovi di dare un marchio privato ai prodotti e di creare un'offerta unica.

5.2 Scelta di un fornitore affidabile

Nella scelta del produttore, considerare i seguenti fattori:

- Esperienza: Cercate fornitori con una comprovata esperienza nella produzione di pannolini.

- Certificazioni: Assicurarsi che il fornitore aderisca agli standard internazionali, come ad esempio FDA, ISO, e CEper garantire qualità e sicurezza.

- Capacità: Assicurarsi che il produttore sia in grado di gestire ordini consistenti e una domanda costante.

- L'innovazione: Collaborare con fornitori che anticipano le tendenze, offrendo design sostenibili e ad alte prestazioni.

6. Confezionamento, personalizzazione e marchio dei pannolini

6.1 Importanza dell'imballaggio

L'imballaggio è un elemento chiave per attirare i consumatori e costruire il riconoscimento del marchio. Potete scegliere tra diverse opzioni di packaging, come ad esempio:

- Imballaggio standard: I sacchi e i cartoni sono comunemente utilizzati per gli ordini di grandi quantità.

- Imballaggio personalizzato: Incorporare design, loghi e marchi unici per distinguere il prodotto dalla concorrenza.

- Imballaggio ecologico: Molti consumatori preferiscono marchi responsabili nei confronti dell'ambiente, per cui offrire imballaggi biodegradabili o riciclabili può essere un punto di forza.

6.2 OEM e private labeling

Lavorare con produttori che offrono Servizi OEM vi permette di personalizzare i prodotti in base alle esigenze specifiche del vostro marchio. Le personalizzazioni più comuni includono:

- Livelli di assorbenza: Personalizzate l'assorbenza in base al vostro mercato di riferimento.

- I materiali: Utilizzare opzioni ecologiche come fibra di bambù o cotone biologico.

- Branding e packaging: Creare un packaging personalizzato che rifletta l'identità del vostro marchio.

7. Innovazioni nel settore dei pannolini per bambini

L'industria dei pannolini è in continua evoluzione, con numerose innovazioni volte a migliorare le prestazioni, il comfort e la sostenibilità:

- Materiali biodegradabili: Un numero sempre maggiore di produttori si sta orientando verso la fibra di bambù, il cotone organico e il SAP biodegradabile per ridurre l'impatto ambientale.

- Pannolini intelligenti: Alcuni pannolini moderni sono dotati di sensori incorporati che avvisano i genitori quando il pannolino deve essere cambiato.

- Additivi minimi: I pannolini privi di sostanze chimiche stanno guadagnando popolarità, per soddisfare i genitori con bambini dalla pelle sensibile.

8. Approfondimenti sul mercato globale

8.1 Mercati emergenti

Regioni come Asia, Africa, e America Latina si prevede che saranno i principali motori di crescita per il settore dei pannolini, a causa dell'aumento del reddito disponibile, della maggiore urbanizzazione e della crescente necessità di prodotti per l'igiene.

8.2 Tendenze dei consumatori

I genitori di oggi sono alla ricerca di:

- Prodotti ecologici: Pannolini fatti di biodegradabile e materiali organici sono sempre più richiesti.

- Opzioni ipoallergeniche: I prodotti per le pelli sensibili sono sempre più diffusi.

- Shopping conveniente: L'ascesa dell'e-commerce ha modificato il comportamento d'acquisto dei consumatori e molti genitori hanno optato per lo shopping online.

8.3 Analisi dei concorrenti

Grandi marchi globali come Pampers, Huggies, e MamyPoko dominano il mercato, ma c'è un ampio spazio per i marchi più piccoli che possono avere successo offrendo unico, di alta qualità, o ecologico prodotti.

9. Caso di studio: Xiamen New EcoCare

Xiamen New EcoCare, produttore leader in Cina, è specializzato in prodotti eco-compatibili. pannolini in fibra di bambù. Con 15 linee di produzione e una capacità mensile di 150 contenitori da 40HQ, fornisce al mercato globale soluzioni di pannolini sostenibili e di alta qualità. I loro prodotti sono certificati da FDA, ISO, e CEgarantendo la conformità agli standard di sicurezza internazionali.

10. Conclusione

Il settore dei pannolini per bambini offre immense opportunità agli imprenditori. Il successo in questo settore dipende da:

- Collaborazione con produttori affidabili che rispettano gli standard di sicurezza e qualità.

- Offrire prodotti innovativi e personalizzabili che soddisfano le esigenze dei consumatori in termini di prestazioni e sostenibilità.

- Costruire una forte identità del marchio attraverso un packaging, un marketing e un coinvolgimento dei clienti efficaci.

Con la giusta strategia, entrare nel mercato dei pannolini per bambini può portare a una crescita e a una redditività a lungo termine. Che vi concentriate sulla produzione, sulla vendita all'ingrosso o sul private labeling, le opportunità sono vaste e i vantaggi significativi. Fate il primo passo oggi stesso e iniziate a costruire la vostra presenza in questo fiorente settore!