Choosing the right manufacturing model is one of the most important decisions a baby diaper brand will ever make.

For B2B buyers entering or expanding in the baby care market, the terms OEM and ODM appear everywhere—supplier websites, quotations, trade shows, and sourcing platforms. Yet many brand owners move forward without fully understanding how this choice affects product control, brand differentiation, compliance responsibility, and long-term scalability.

In 2026, as competition increases and buyer expectations rise, choosing between OEM and ODM baby diaper manufacturing is no longer a technical detail. It is a strategic decision that shapes your brand’s future.

In this article, New EcoCare breaks down the real differences between OEM and ODM from a practical B2B perspective, helping private label buyers make informed, future-proof decisions.

Table of Contents

Understanding OEM and ODM in Baby Diaper Manufacturing

Before comparing the two models, it’s important to clarify what OEM and ODM really mean in the hygiene products industry.

What OEM Means for Baby Diapers

OEM (Original Equipment Manufacturer) refers to a manufacturing model where:

The brand owner defines the product concept

The factory produces according to customized specifications

Product identity belongs primarily to the brand

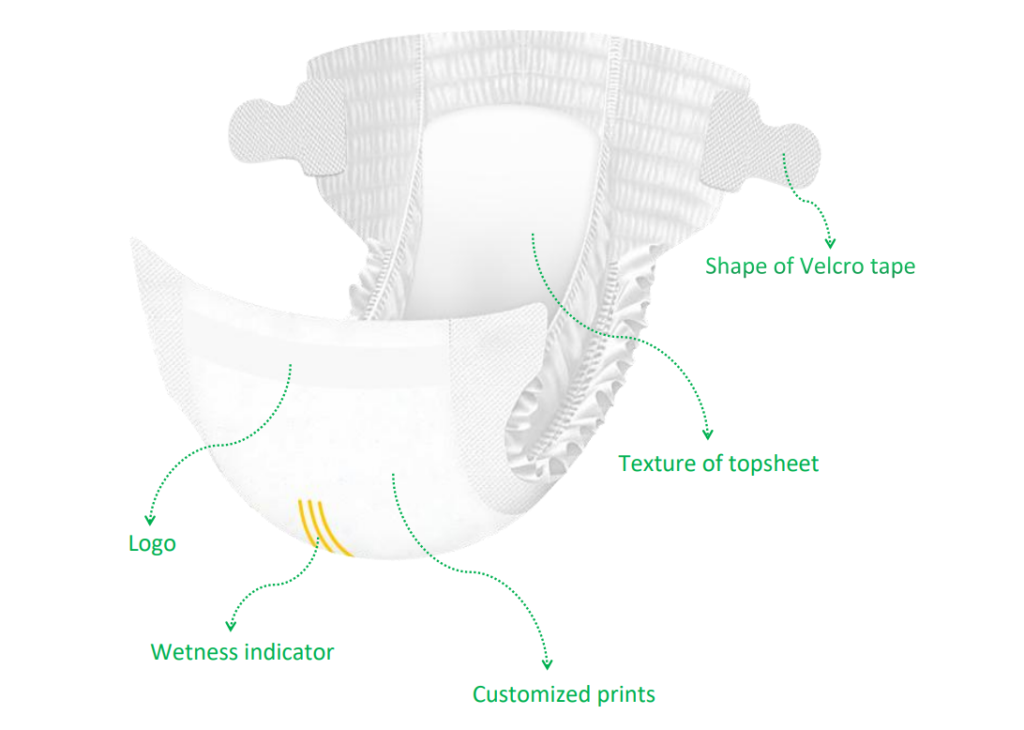

In baby diaper OEM projects, brands typically control:

Materials selection

Structural design priorities

Performance targets

Brand positioning

The manufacturer provides technical execution and production expertise.

What ODM Means for Baby Diapers

ODM (Original Design Manufacturer) refers to a model where:

The manufacturer owns the product design

The brand selects from pre-developed diaper solutions

Customization is limited

ODM baby diapers are usually based on existing designs that can be quickly branded and launched.

This model prioritizes speed and simplicity over deep differentiation.

Why the OEM vs ODM Decision Matters More in 2026

In earlier years, many brands could succeed with minimal product differentiation. That is no longer the case.

Today’s market realities include:

Parents comparing products across regions

Retailers demanding clearer differentiation

AI search surfacing product details more transparently

Compliance scrutiny increasing in multiple markets

As a result, the manufacturing model you choose directly impacts your competitive resilience.

OEM Manufacturing: Control, Differentiation, and Long-Term Value

For many private label brands, OEM baby diaper manufacturing remains the preferred path—especially for those aiming to build premium or mid-to-high positioning.

1. Stronger Product Control

OEM allows brands to influence how the diaper performs, not just how it looks.

This includes control over:

Skin-contact materials

Absorption logic

Fit and comfort balance

Design trade-offs

For B2B buyers, this control becomes critical when responding to market feedback or regional preferences.

2. Clearer Brand Differentiation

OEM manufacturing supports unique product identities.

Even small adjustments—such as softness level, core structure, or fit profile—can help brands stand out in crowded markets. This differentiation is difficult to achieve through ODM alone.

3. Better Alignment With Premium and Sensitive-Skin Segments

As discussed in many market trends, premium diaper growth is often driven by comfort and skin performance.

OEM projects allow brands to design products that align with:

Sensitive-skin positioning

Long-wear comfort expectations

Reduced irritation risks

These are difficult to guarantee when using standardized ODM designs.

4. Scalability Without Frequent Supplier Switching

OEM manufacturing is often misunderstood as complex or slow. In reality, once specifications are stabilized, OEM production can scale efficiently.

For growing brands, this means:

Fewer product disruptions

More consistent quality

Stronger supplier relationships

ODM Manufacturing: Speed and Simplicity With Trade-Offs

ODM baby diapers still play a role in certain business scenarios, especially for brands with limited resources or urgent timelines.

When ODM Makes Sense

ODM may be suitable if:

You need to launch quickly

You are testing a new market

Product differentiation is not a priority

Budget constraints limit customization

In these cases, ODM offers a faster entry point.

The Hidden Limitations of ODM

While ODM can reduce initial complexity, it introduces other challenges:

Limited ability to adjust performance

Higher risk of product similarity with competitors

Reduced control over future improvements

As markets mature, these limitations often become more visible.

Cost Considerations: OEM vs ODM Is Not Just About Price

Many buyers assume ODM is always cheaper than OEM. In practice, the cost difference depends on volume, customization depth, and long-term planning.

OEM Cost Structure

OEM costs reflect:

Material choices

Custom development effort

Production efficiency

Volume commitments

While initial development may require more planning, unit costs often become competitive at scale.

ODM Cost Structure

ODM costs are often:

Lower upfront

Less flexible over time

Subject to design ownership limitations

In long-term scenarios, ODM products may become less cost-efficient due to limited optimization options.

Intellectual Property and Brand Protection

Another critical difference between OEM and ODM lies in design ownership.

In OEM projects, brands typically retain control over specifications

In ODM models, the manufacturer controls the core design

For private label brands planning long-term growth, this distinction matters—especially when expanding across regions or channels.

Compliance and Market-Specific Requirements

As regulations evolve, manufacturers and brands must adapt quickly.

OEM manufacturing allows:

Faster material adjustments

Market-specific compliance adaptation

Controlled documentation processes

ODM designs may require revalidation or may not fully align with certain market expectations.

A Practical Decision Framework for B2B Buyers

When choosing between OEM and ODM baby diapers, consider these questions:

Do you plan to build a long-term brand or a short-term SKU?

Is product performance part of your brand promise?

Will you expand into multiple markets?

Do you expect to refine your product over time?

If most answers are “yes,” OEM manufacturing is usually the stronger foundation.

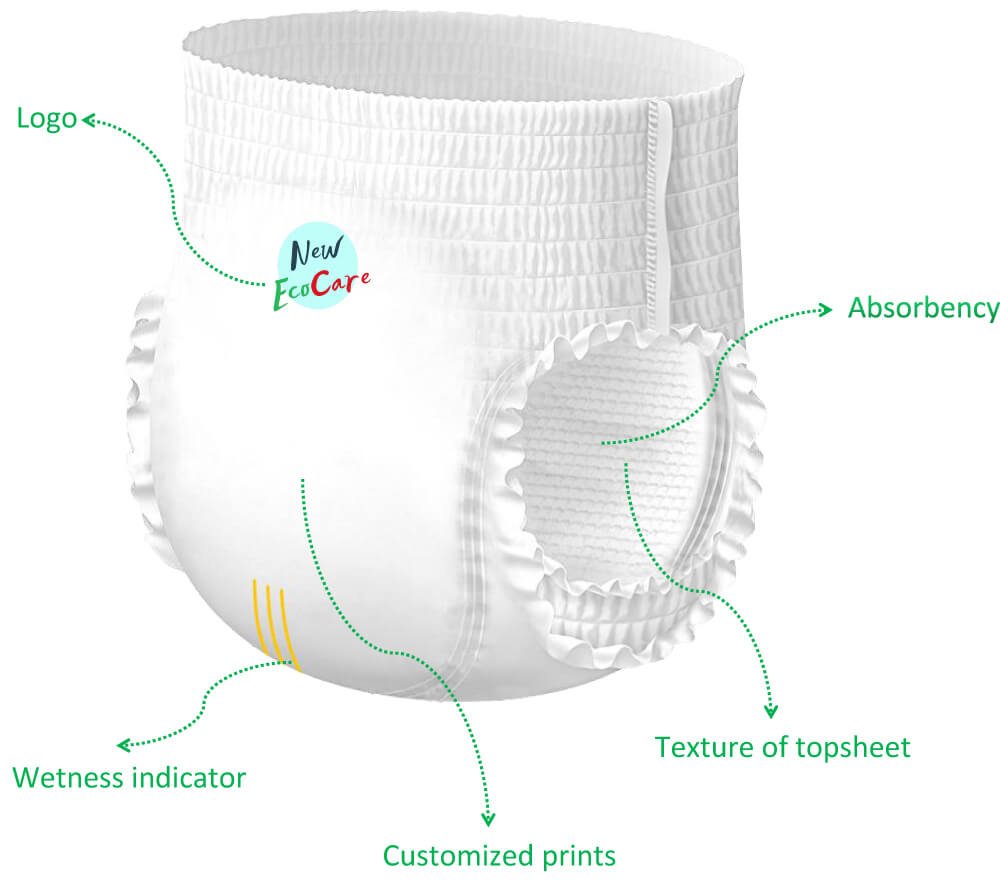

How New EcoCare Supports Both Models—Strategically

At New EcoCare, we work with both OEM and ODM buyers—but with a focus on fit, not volume.

Our role is to help brands:

Understand their real needs

Choose the right development path

Avoid unnecessary complexity

Build products that align with long-term goals

In many cases, brands start with limited OEM customization and expand gradually as their market grows.

Final Thoughts: Choose the Model That Matches Your Vision

OEM and ODM are not competing concepts—they are tools. The key is choosing the one that matches your brand ambition, risk tolerance, and growth plan.

In 2026, successful baby diaper brands are those that think beyond speed and price. They invest in manufacturing decisions that support credibility, adaptability, and trust.

At New EcoCare, we believe that the right manufacturing model is not the fastest one—but the one that allows your brand to grow with confidence.